Temporary prostheses are a crucial part of many dental treatments, serving as interim restorations while permanent crowns, bridges, or veneers are being fabricated. They aren’t just placeholders; they play vital roles in protecting the prepared tooth, maintaining the correct bite and tooth position, ensuring gum tissue health, and allowing patients to eat, speak, and smile confidently.

Traditionally, temporaries were often made chairside from auto-curing acrylics, which could be time-consuming and often lacked optimal esthetics and fit. However, digital dentistry, particularly CAD/CAM milling with advanced materials like multilayer PMMA, has transformed temporary prosthesis fabrication, offering superior results and a better patient experience.

Multilayer vs. Monolayer: Elevating Patient Options

When it comes to milled temporary prostheses, two primary types of PMMA blocks are common: monolayer and multilayer.

Monolayer PMMA offers a uniform, single shade throughout the block. These temporaries are durable and functional, serving the essential protective role well. They are a good, economical option when the temporary restoration is in a less visible area or when primary concern is function and protection rather than high-level esthetics.

Multilayer PMMA, on the other hand, takes temporary esthetics to a whole new level. These blocks are designed with multiple layers of PMMA that transition in shade and translucency, mimicking the natural look of a real tooth. Imagine a natural tooth, lighter and more translucent at the biting edge and gradually becoming warmer and more opaque towards the gum line – multilayer PMMA replicates this. With options available in the full range of VITA 16 shades and often bleach shades, multilayer temporaries can be closely matched to the patient’s existing dentition, providing a truly natural appearance.

Offering multilayer temporary options allows dental professionals to provide patients with a significantly more esthetic interim solution, especially for temporary crowns and bridges in the smile zone. This enhances patient comfort, confidence, and satisfaction throughout the treatment process.

The Digital Workflow: Fast, Precise Fabrication

The digital workflow makes fabricating high-quality multilayer PMMA temporary prostheses efficient and precise. It starts with taking a digital impression using an intraoral scanner. This eliminates the need for traditional, often uncomfortable, impression materials.

Once the digital impression is captured, the 3D data is instantly shared with the dental laboratory. The dental laboratory then uses advanced CAD/CAM milling software to design the temporary prosthesis and sends the design to a milling machine.

With the advanced CAD/CAM milling machine, the dental laboratory can fabricate the multilayer PMMA temporary prosthesis quickly and accurately from the pre-shaded block. The machine mills the restoration to the exact specifications of the digital design, utilizing the layered structure of the multilayer PMMA block to achieve the desired esthetic outcome. This digital fabrication process is faster and more consistent than traditional methods, ensuring a well-fitting and esthetic temporary prosthesis in a short amount of time.

Basic Workflow for Fabricating Multilayer PMMA Prostheses

| Step | Action |

|---|---|

| 1 | Dentist prepares the patient’s tooth/teeth. |

| 2 | Dentist uses an intraoral scanner to take a digital impression (3D scan). |

| 3 | Digital scan files are sent electronically to the dental laboratory. |

| 4 | Dental technician uses CAD software to design the temporary prosthesis. |

| 5 | Design is positioned virtually in a multilayer PMMA block in the software. |

| 6 | CAM software prepares the design for milling and selects milling paths. |

| 7 | Dental technician places the multilayer PMMA block in the milling machine. |

| 8 | The CAD/CAM milling machine mills the temporary prosthesis precisely. |

| 9 | Milled temporary is removed from the block. |

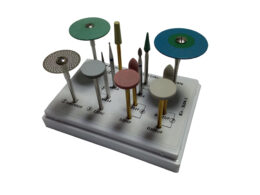

| 10 | Temporary prosthesis is finished and polished. |

| 11 | Completed multilayer PMMA temporary is delivered to the dentist. |

| 12 | Dentist cements or places the temporary prosthesis in the patient’s mouth. |

For the dental labs seeking high quality multilayer PMMA blocks, looking no further than Dental Lab Shop, they have huge in stock, and ready to go multilayer PMMA materials, open system, and Zirkonzahn, Amann Girrbach, CEREC system also available, VITA 16 shades available. Learn more about Multilayer PMMA Blocks thourgh this useful page.